10 Discovery Way

Stainless steel tubing is the most versatile metal alloy used in manufacturing. Type 304 accounts for nearly 50% of all stainless followed by type 316.

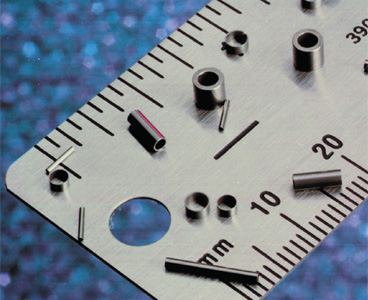

Cut-to-length tubing – Eagle Stainless Tube’s facilities enable cutting and deburring 1 ½ “ diameter tubing in quantities from a single piece to millions of pieces. Burr free production. Removing burrs creates a smoother, more functional durable metal part.

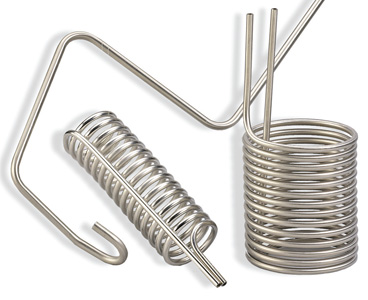

Bending – Stainless steel can be bent in multiple directions and angles without excessive distortion, wrinkling or fracturing. Things to keep in mind when bending are the bend radius, yield strength, material thickness and if it is welded or seamless.

End forming – Ensuring repeatability for proper mating of flare and end-reduced tubes. Closed-end tubes are spun closed and welded shut in various end configurations including round, flat or pointe. Advantages to end forming tubes is an enhanced tube strength, connectivity improvements and increased sealing capabilities.

CNC Machining – can result in improved accuracy, increased production speeds, enhanced safety, increased effi ciency, and cost savings.

Thoughts of tubing may offer circular images. Tubing comes in many shapes, sizes and thicknesses. Round, oval, rectangular or square, stainless steel tubing is versatile and popular. Formed components are ideal for uses in surgical devices, heat exchangers, instrumentation and handling equipment.

Delivering stainless steel, high nickel alloy components to customers in the medical, aerospace and industrial industries. Stainless steel is a commonly used material in applications ranging from medical instruments, chemical storage, transportation of liquid and gasses and other industrial applications.

The multitude of benefits offered by stainless steel not only enhance its quality and durability, but also contribute to sustainability. The exceptional strength, corrosion resistance, and longevity contribute to the sustainability by minimizing the need for frequent replacement and reducing environmental impact through its long lasting performance.