SMW-AUTOBLOK is among the leading manufacturers worldwide of workholding for turning and grinding on machine tools with production facilities in Meckenbeuren, Germany and Caprie, Italy. With the establishment of SMW-electronics we can service important new target markets such as electronics, automation, and handling, robotics/cobotics and intralogistics.

We develop, produce, and support all our products, and thus set worldwide standards in the industry. We employ over 1000 people globally, among these about 300 in Meckenbeuren, Germany.

Direct subsidiaries and agents worldwide, enable us to offer a worldwide competent service and support.

SMW-Autoblok has evolved from a conventional producer of workholding devices to a high-tech manufacturer of mechanics, electronics, and software for CNC Automation. To combine our competences for smart products and to create further and forward-looking synergies, we launched the new business unit SMW-electronics. SMW-electronics is a leader in developing products that automate and digitize CNC processes, as well as other automation applications.

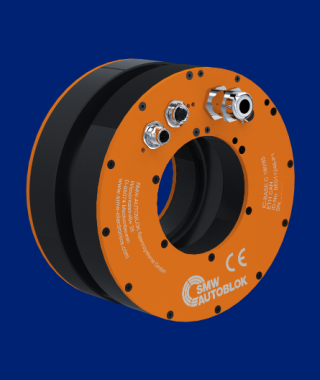

SMW-electronics incorporates core technologies of inductive energy and data transmission, sensors, software, and mechatronics to realize this vision. Products such as our MotiAct Mechatronic grippers combined with our Inductive Couplers enable the full capabilities of Industrial Robots and Cobots in many industrial applications.

SMW-electronics offers automation solutions for target markets including machine tools, automation and robotics, electric drive technology, automotive, intralogistics, industrial and agricultural equipment, packaging industry, energy (oil, gas, wind), aerospace and medical technology.