High-Performance Polymer Solutions & Technologies

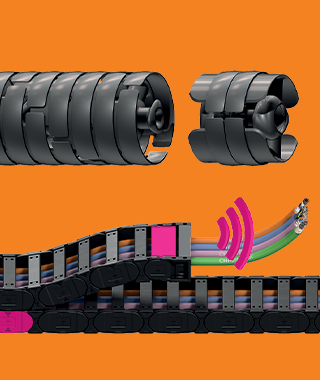

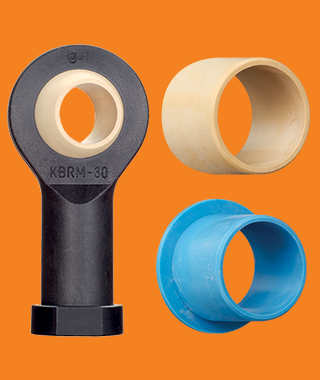

igus® develops industry-leading plain, spherical, and linear bearings made from polymer materials along with plastic cable carrier systems and continuous-flex cables.

igus’ tribologically-optimized polymer blends are comprised of base materials for wear resistance, reinforcing fibers for high forces, and solid lubricants that eliminate the need for external oil and grease. In addition to being dry-running, igus’ polymers are maintenance-free, lightweight, and resistant to dirt, dust and chemicals.

igus works with customers to find the best, most cost-effective solution for all applications via online chat, phone, email, or on site. Online tools and lifetime calculation, custom part manufacturing, prototyping, testing and more is available.

igus® has been manufacturing engineered plastics for nearly 60 years and develops all of the technology and materials behind their products. The family-owned company is committed to using its innovative materials to develop creative solutions and exceed customer expectations while delivering fast, accurate service.

igus centers their business around four main product lines focused on the idea of “motion plastics”:

igus extensively tests all of their products under real-world conditions in a 41,000-square-foot testing facility in Cologne, Germany. Data from these tests power various online tools to help customers spec the best materials and parts for their application. With over 80,000 products in stock within their Rhode Island warehouse, igus is able to ship up to 96% of orders within 24 hours.

The igus team of sales engineers is available coast to coast from 8AM to 8PM ET, along with a dedicated team of technical sales experts located across North America for quick on-site assistance. igus also offers complimentary online CAD files and free product samples.

As a producer of plastic components, reducing environmental impact is a primary focus for igus. To that end, igus recycles and reuses 99% of their plastic waste and has also made the switch to green electricity and climate-neutral gas with plans to reach CO2 neutrality by 2025.